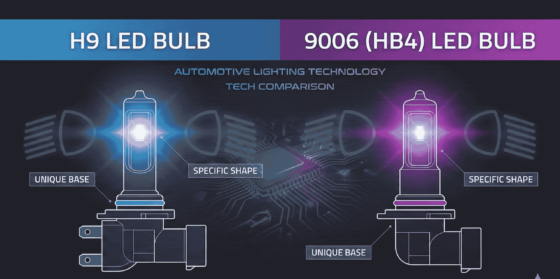

Choosing between H9 LED and 9006 (HB4) LED bulbs requires more than comparing lumen claims. We provide a full, engineering-level breakdown covering base geometry, optical behavior, heat dynamics, LED conversion fundamentals, legality, real-world performance, and buying guidance. This guide is designed to outperform generic summaries by delivering accurate, structured, and deeply usable information for automotive lighting upgrades.

1. Overview: H9 vs 9006 (HB4) LED Bulb Families

H9 and 9006 represent different bulb families, each engineered for distinct reflector optics, thermal profiles, and vehicle applications.

| Feature | H9 | 9006 / HB4 |

| Base Type | PGJ19-5 | P22d (90°) |

| OEM Halogen Wattage | ~65 W | ~51–55 W |

| OEM Halogen Lumens | ~2,100 lm | ~1,000–1,200 lm |

| Common Use | High beam / high-output low beam | Low beam / fog lamps |

| Interchangeability | Not compatible | Not compatible |

2. Physical & Electrical Differences That Prevent Swapping

2.1 Base Geometry & Locking Tabs

The core reason H9 and 9006 bulbs cannot be interchanged is their base design and seating interface.

- H9 → PGJ19-5: Narrow keyed tabs and a specific rotational alignment.

- 9006/HB4 → P22d (90°): A 90-degree keyed base requiring a different insertion angle.

These base types ensure the bulb sits at the precise height and angle required for the reflector’s focal point. Any mismatch leads to:

- Misaligned light source

- Unusable beam pattern

- Severe glare for oncoming drivers

- Housing damage from improper fit

2.2 Wattage, Filament Design & Thermal Load

H9 halogens run 10–14 W hotter than 9006 units. Even though LEDs consume less power, the housing design still follows the original halogen heat profile:

- H9 housings tolerate higher filament temperatures.

- 9006 housings may not handle the thermal load of aggressive LED drivers/heatsinks.

3. Why Lumen Numbers Alone Are Misleading

3.1 Filament Position vs LED Chip Placement

Both bulb families rely on precise filament positioning. LED conversions must mimic filament geometry within ±0.2 mm to maintain proper:

- Hotspot intensity

- Horizontal cutoff

- Foreground/background balance

Cheap LEDs place emitter chips incorrectly, resulting in:

- Over-illumination of foreground

- Lost throw distance

- Blinding scatter above cutoff

3.2 Reflector vs Projector Optics

The same LED kit can perform very differently depending on housing type:

- Projectors offer better focus and tolerate minor emitter deviations.

- Reflectors are extremely sensitive to emitter misalignment.

Even a perfect H9 LED will fail in a 9006 reflector housing, and vice versa.

4. LED Replacements: What Changes and What to Know

4.1 Form Factor & Socket Compatibility

Many LED kits claim H8/H9/H11 compatibility, but tab geometry and connector orientation are not identical. Always verify:

- Tab alignment

- Connector style

- Driver box clearance

4.2 Power Draw vs Claimed Lumens

LEDs typically consume 20–40 W but often claim:

- 10,000–30,000 lumens (usually exaggerated)

- “CSP/COB super chips” (marketing terms)

The real determining factor is beam quality, not raw lumen claims.

4.3 Cooling System Requirements

LED bulbs use:

- Active cooling (micro fans)

- Passive cooling (heat sink fins)

- Hybrid cooling (fan + copper braid)

Enclosed housings may:

- Overheat LED drivers

- Trap heat around the fan

- Require dust-cap modification

5. Fitment, Clearance & Practical Installation Considerations

5.1 Verify the Exact Bulb Type

The correct bulb designation is printed on:

- Your owner’s manual

- Your existing bulb’s base

- Vehicle parts database

Do not assume H9 fits a 9006 socket or vice versa.

5.2 Check Backside Clearance

LED assemblies protrude farther than halogens due to:

- Heatsinks

- Fans

- Driver boxes

Measure depth before purchasing.

5.3 CANbus & Error Handling

Many vehicles detect bulb resistance. LEDs can trigger:

- “Bulb Out” warnings

- Rapid flashing

- Error codes

Solutions:

- CANbus resistors

- Compatibility drivers

- Built-in anti-flicker modules

6. Safety, Legality & Road Compliance

6.1 Legal Status of LED Bulb Swaps

In many regions, LED retrofit bulbs are:

- “Off-road use only”

- Not DOT/SAE/ECE certified for halogen housings

Improper beam patterns can fail vehicle inspections.

6.2 Glare Risk & Beam Aiming

Even premium LED bulbs require a proper headlight aiming procedure. Misalignment by just a few degrees can produce:

- Severe glare

- Reduced down-road visibility

- Safety hazards in rain or fog

7. Real-World Output: H9 vs 9006 Performance Breakdown

7.1 H9 Halogen

- ~65 W

- ~2,000–2,100 lumens

- Shorter lifespan

- Stronger hotspot intensity

- Often used for high beams

7.2 9006 (HB4) Halogen

- ~51–55 W

- ~1,000–1,200 lumens

- Cooler operation

- Longer lifespan

- Common for low beams/fog lamps

7.3 LED Conversions

Quality LED bulbs (from reputable brands) offer:

- Higher usable lux

- Lower power consumption

- Reduced heat at the reflector

- Improved color temperature (5000–6500K)

But only if emitter geometry correctly reproduces the halogen filament.

8. Step-By-Step LED Buying Checklist

- Verify your OEM bulb type (H9 or 9006).

- Identify the headlight function (low beam, fog, or high beam).

- Choose an LED kit that offers:

- Photometric beam test results

- Precise emitter positioning

- High thermal efficiency

- Photometric beam test results

- Check rear clearance and ensure fitment inside dust covers.

- Ensure CANbus compatibility if your vehicle uses bulb monitoring.

- Perform proper headlight aiming after installation.

Conclusion

Both H9 and 9006 LED bulbs can drastically improve road visibility when used correctly, but only when matched to the proper socket type, reflector/projector design, and optical geometry. H9 bulbs deliver higher raw output but can only be used in H9-compatible housings. 9006 bulbs prioritize balanced low-beam performance and are engineered for different reflector optics.

For a safe, legal, high-performance upgrade:

- Use only the bulb family your vehicle was designed for.

- Choose LEDs with precise emitter alignment and independent beam testing.

- Verify cooling clearance, CANbus compatibility, and proper aiming.

This ensures maximum visibility without glare, preserving both safety and compliance.

FAQs

Can I replace a 9006 bulb with an H9 LED?

No. The bases, locking tabs, and emitter positions differ. Forcing it results in a dangerous beam pattern and possible housing damage.

Is an H9 LED “better” than a 9006 LED?

Neither is inherently superior. The correct choice depends on your vehicle’s required bulb family and optical design.

Will LED bulbs void my warranty?

Some manufacturers restrict modifications. Always check your warranty terms and local regulations.